JSL SUMITOMO Stainless Steel Seamless Tube, For Boiler, Material Grade

KA-STB(P)A24J1, ASTM A213 T23/A335 P23, ASME SA213 T23/SA335 P23 Code Case 2199. Developed jointly with Mitsubishi Heavy Industries, Ltd. Features 1High-strength 2.25Cr ferritic steel tubes (tubes and large-diameter thick-wall pipes) The strength is about 1.8 times higher than that of conventional STB(P)A24.

ASTM A213 ASME SA213 T9 Seamless AlloySteel Boiler TubesBoiler Tubes

This chapter discusses the primary requirements for boiler tube materials, including oxidation and corrosion resistance, fatigue strength, thermal conductivity, and the ability to resist creep and rupture. It also provides information on various steels and alloys, covering cost, engineering specifications, and ease of use. Topics

Reyhan Blog Boiler Tube Material Specification

Global Marketing for Tube & Pipe www.TubeSolution.com Material Comparison Tables (ASTM, KS, JIS, DIN, BS, NF, UNI). Resistance Welded Boiler Tubes Grade A K01200 STBH 340 / STB 35 D3563 / G3461 St 37.8 17177 1.0315 (7) 3059. C-Steel Boiler Tube for High Pressure Service K01201 STBH 340 / STB 340 D3563 / G3461 (30) St

Swaging Boiler Tubes, Steel Grade Ms, Material Grade Seamless, ID

ASTM A209 t1a material offer tight tolerances and offers stronger physical properties compared to other mechanical tubing. It is suited for applications that needs toughness, wear resistance, high strength than other grades. The choice of SA 209 T1a tube is often determined by the tensile strength and ruling section of the steel.

Boiler tubes, carbon steel

SA210 A1 is a Seamless medium carbon steel Boiler Tube used in super heater, heat exchangers, condensers, marine application, refineries, paper pulping, petrochemical applications, pressure vessels, and general engineering applications. It is also used in coal, thermal and oil power generation plants.

Seamless boiler tubes Steel grade (JIS) A/SA 192 , A/SA 210 , A/SA 213

BOILER TUBE GRADES CARBON STEEL SA178 Carbon steels show mild corrosion resistance and fair strength up to 1000F. However, their usage above 800F must take into account the susceptibility to graphitization. Graphitization has not been a significant problem in thicknesses encountered in boiler tubing. Use of heavy section pipe above 800F, however, is not recommended. […]

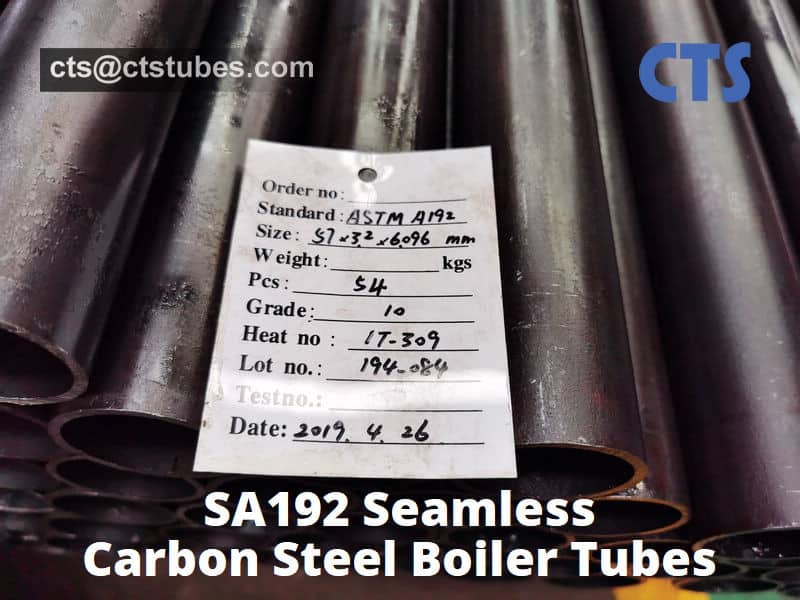

SA192 Seamless Carbon Steel Boiler Tubes CTS Tubes

1. Pipes 2. Tubes 3. Forgings 4. Castings 5. Fittings 6. Valves 7. Nuts and Bolts ASME Material Specifications for Pipes: 1. SA 53: Hot-dipped, Zinc-coated, Welded, And Seamless Pipes 2. SA 106: Seamless Carbon Steel Pipe For High-temperature Service 3. SA 312: Seamless, Welded, And Heavily Cold Worked Austenitic Stainless Steel Pipes 4.

Swaging Boiler Tubes, Steel Grade Ms, Material Grade Seamless, ID

Chapter 4: Materials for Boiler Tubes Doi: https://doi.org/10.31399/asm.tb.fibtca.t52430087 Published: 2018 Share Search within book: Abstract Boilers are often classified based on the maximum operating temperature and pressure for which they are designed.

12.7 To 127 Round Stainless Steel Boiler Tubes, Material Grade SS316L

Tube material could be in alloy and stainless steel, manufacturing type in seamless of hot rolled and cold drawn. Common grades are T9, T11, T12, T21, T22, T91 and stainless grades in TP304 or TP316. ASTM A213 tubing used in high temperature services especially for the boiler and superheater.

SA 210 Grade A1 Boiler Tube and ASTM A210 Condenser Tubing supplier

For all grades specify qualification of welding procedure and hydrostatic test per ASTM Standard. (20) Specify maximum hardness of 99 HRB or 235 HB. (21) Specify silicon content of 0.15 ∼ 0.5%. (22) Specify maximum hardness of 187 HB. (23) Consider differences in dimensions and tolerances.

Stainless Steel Boiler Tubes, Material Grade Ss316 at best price in

These five alloys cover probably 85% to 90% of the steels used of the many acceptable grades listed in the Code. There are others that may find specific applications, for example 1/2 Chromium-1/2 Molybdenum alloy SA213 T-2, 9 Chromium-1 Molybdenum alloy SA213 T-9, and corrosion-resistant, high-temperature alloys of nickel and chromium, SB-407.

IBR ERW Boiler Tubes 3059, Steel Grade Thickness 14 Swg To 8 Swg

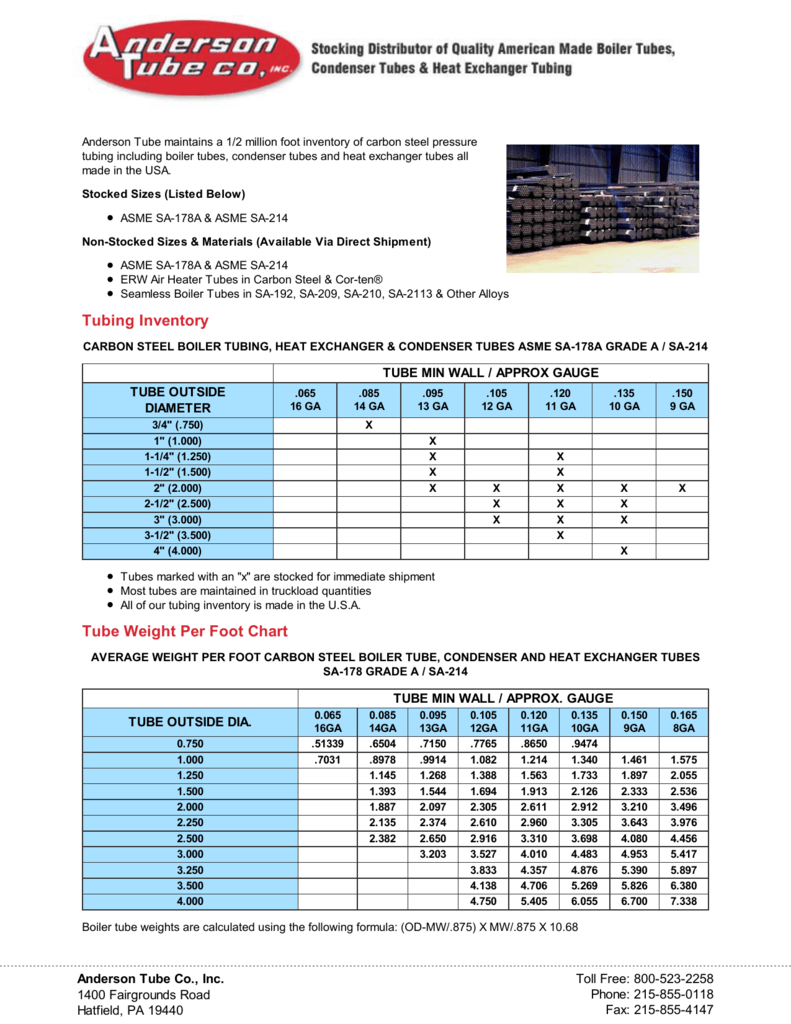

SA178A / ASTM A178 Grade A SA 178Ais an ERW (electric resistance welded)low carbon steel boiler tube used in super heaters, water wall panels, heat exchangers, condensers, marine application, refineries, paper pulping, It is also used in coal, thermal and oil power generation plants.

Stainless Steel Round Ms Seamless Boiler Tube, Material Grade SS304 at

Grade: A192 / SA192 Heat Treatment: Hot-finished tubes need not be heat treated. Cold- finished tubes shall be heat treated after the final cold-finishing at a temperature of 1200°F [650°C] or higher. Test requirement: ASTM A192 / ASME SA192 Tube Chemical Compositions ASTM A192 / ASME SA192 Tube Mechanical Tests Required

Boiler Pipe,ASTM A213 Boiler Pipe Threeway Steel Co.,Ltd

· VdTÜV material data sheet 547 (03.2007), Federal Republic of Germany 1.5 Available Sizes DMV 347 HFG austenitic stainless steel is used to manufacture seamless austenitic reheater and superheater boiler tubes. This grade is suitable for all commonly used aus-tenitic reheater and superheater boiler tube sizes and also in the most advanced coal

Stainless Steel Hydraulic Boiler Tube, Material Grade SS304 at Rs 250

9 Stays 10 Books 11 References ASME Code Boilers Marty Know wrote : Materials accepted for construction of an ASME code vessel. Shell - SA106 B Plate - SA285 grade C/SA515 grade 70/SA516 grade 70 Steel Tubes - SA178 grade A (welded) SA192 (seamless) Copper Tubes - no Code specification Staybolts - SA36/SA675 Threaded couplings - SA105 3M (3000#)

Carbon Steel Seamless Boiler Tube, Material Grade Astm at Rs 500/mtr

Standards and material for steel pipe is available at carbon, alloy, and stainless steel material. Carbon steel: ASTM/ASME A/SA 106, ASTM A179, ASTM A192, ASTM/ASME A/SA 210, ASTM A333 Gr 1, 6,7 to Gr 9, Alloy steel: ASTM/ASME A/SA 213 T1, T2, T5, T9, T11, T12, T22, T91, T92; ASTM A335 P1, P2, P5, P9, P11, P12, P22, P91, P92